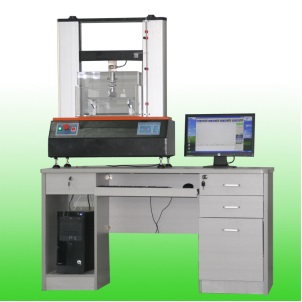

Three point bending tester DR-6000W

This tester is suitable for conducting three-point bending, four point bending and compression tests on mobile phone glass, tablet computer glass, LCD glass and other materials. It can conduct tests and provide data (such as JC/T676-1997 glass material bending test method, BSEN1288-3-2000 building glass) according to the customer's product requirements according to GB, DIN, ISO, JIS, ASTM and other international standards. Determination of glass bending strength), in line with Samsung glass lens test standards.

Three point bending tester DR-6000W

1、 Purpose:

This tester is suitable for conducting three-point bending, four point bending and compression tests on mobile phone glass, tablet computer glass, LCD glass and other materials. It can conduct tests and provide data (such as JC/T676-1997 glass material bending test method, BSEN1288-3-2000 building glass) according to the customer's product requirements according to GB, DIN, ISO, JIS, ASTM and other international standards. Determination of glass bending strength), in line with Samsung glass lens test standards. The computer controlled Windows operating system is used to dynamically display the test data curve, and automatically obtain the parameters such as the maximum force, maximum deformation, bending stress, bending strength, compression strength, compression force, elastic modulus, elongation, etc. (according to the user's requirements, which test is needed to equip the corresponding fixture). The test curve and data results can be dynamically displayed and arbitrarily set on the computer, which makes the curve operation easier. relaxed. You can edit curves anytime and anywhere. Full electronic display and monitoring such as stacking, separation, scaling, printing, etc. The whole process of data acquisition is not divided into stages. The servo motor and reducer are used to drive the ball screw to make the whole bench move up and down. The characteristics of balance and stability greatly extend the service life and efficiency of the testing machine; The whole system can more accurately reflect the force value, deformation and time, and connect the computer to realize full computer control and print the standard test report. It is mainly used in colleges and universities, scientific research institutions, quality testing centers, enterprise quality testing departments, laboratories and other laboratories to test the physical and mechanical properties and process properties of materials, and is favored by users.

2、 Operating principle and performance:

The servo motor is used to drive the moving beam up and down through the transmission mechanism to realize the test loading process. This machine adopts advanced full digital control system for control and measurement, and uses computer to dynamically display the test process and test curve, and conduct data processing. After the test, the curve can be amplified by software for data re analysis and editing.

3、 Technical parameters:

1. Maximum test load: 5kN;

2. Force measurement accuracy class: 0. Level 5;

3. Effective force measuring range: 0. 2% - 100% FS, "FS" is full scale;

4. Test force error: within ± 1% of the indicated value;

5. Test speed adjustment range: 0. 001-500mm/min (stepless speed regulation);

6. Speed accuracy:+0. 5%;

7. Resolution of test force indication: ± 1/250000 of the maximum test force (resolution of the whole process remains unchanged);

8. Deformation measurement range: 0. 2—100%FS;

9. Deformation measurement error: ± 0 of the indicated value. Within 5%;

10. Deformation resolution: 1/250000 of the maximum deformation (the whole process resolution remains unchanged);

11. Safety device: electronic limit protection;

12. Overload protection: automatic protection when the maximum load exceeds 10%;

13. Data acquisition frequency: 100times/sec;

14. Effective test width: 400mm;

15. Maximum stroke: 400mm;

16. External dimension of main engine (length × width × height): 750 × 400 × 920 (mm);

17. Power supply: single-phase AC220V/0. 4kW;

18. Main engine weight: 80kg.

4、 Main configuration:

1. One 5kN host;

2. The machine contains:

a) One 5000N high-precision tension and compression sensor (or optional);

b) One set of imported servo system;

c) A set of high-precision synchronous belt reduction system;

d) Two sets of high-precision ball screw;

e) TM2101BDP measurement and control system and a set of software

The measurement and control system can conduct tensile, compression, bending, peeling, constant pressure and other tests, and can be prepared according to GB, ISO, ASTM and other standards according to customer product requirements. It can automatically calculate the maximum test force, bending strength, elastic modulus, elongation and other parameters.

3. Fixture configuration (two sets)

a) One set of three-point bending fixture (the size is customized according to the customer's product requirements)

b) One set of four point bending fixture (the size is customized according to the customer's product requirements)

4. One set of special tools and one set of protective cover for testing machine

5. Dell brand computer, printer, data connection, testing machine software CD.

-

CS tester FSM-6000LE glass surface stress meter

Learn more>>

CS tester FSM-6000LE glass surface stress meter

CS tester FSM-6000LE glass surface stress meter, with small automatic measurement error, is widely used in chemical flat glass manufacturers such as LCD and touch panel manufacturers. Tempered glass stress meter, FSM-6000LE glass surface stress meter is used to measure chemically strengthened and physically strengthened glass

Learn more>>

-

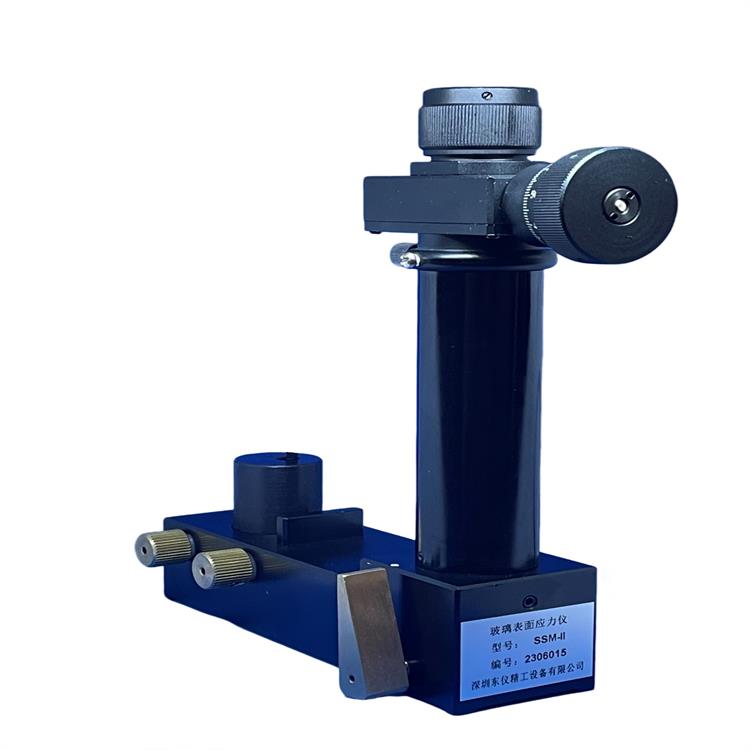

SSM-II glass surface stress meter

Learn more>>

SSM-II glass surface stress meter

SSM-II glass surface stress meter uses the optical waveguide effect caused by the tin diffusion layer on the surface of float glass to measure the surface stress quantitatively.

Learn more>>

-

Surface stress tester FSM-6000LE

Learn more>>

Surface stress tester FSM-6000LE

It is mainly used to measure the surface stress of chemically strengthened and physically strengthened glass

Learn more>>

-

Polarization stress meter LSM-4403

Learn more>>

Polarization stress meter LSM-4403

The automatic measurement error of the tempered glass stress meter FSM-6000LE is small. It is widely used in chemical flat glass manufacturers and touch panel manufacturers, such as LCD screen manufacturers. Tempered glass stress meter, FSM-6000LE glass surface stress meter is used to measure the surface stress of chemically strengthened and physically strengthened glass.

Learn more>>

Professional agent of well-known instruments and equipment at home and abroad

Provide professional laboratory solutions and equipment support

- Strong technical R&D team

- Experienced and excellent technology and innovative ideas

- High quality product supporting star service

Leave us a message , please fill in the correct information so that we can contact you at the first time!