Four point bending tester DR-6001

Standards met:

GB/T16491-1996 Electronic Universal Testing Machine

Application industry:

Metrological quality inspection; Rubber and plastic; Metallurgical steel; Machinery manufacturing; Electronic appliances; Automobile production; Textile chemical fiber; Wire and cable; Packaging materials and food; Instruments and Apparatuses; medical apparatus and instruments; Civil nuclear energy; Civil aviation; Colleges and universities; Scientific research laboratory; The commodity inspection arbitration and technical supervision departments; Building materials ceramics; Petrochemical industry; Other industries.

Four point bending tester DR-6001

Main functions:

It is used for tensile, compression, bending, shearing, peeling, tearing and other tests of various metal and non-metallic material samples, as well as special tests of some products.

Main features:

1: With high-speed DSP platform, its high integration, powerful control, data processing ability, and high reliability are unmatched by other processors.

2: The full digital, three closed loop (force, deformation, displacement) control system based on neuron adaptive PID algorithm is adopted to realize the full digital, three closed loop control of force, deformation, displacement. Each control loop can be automatically switched, and the smooth transition without impact can be achieved when switching between modes.

3: It can control and maintain the test force, deformation, displacement and other rates.

4: Online identification of closed-loop control parameters.

5: High precision 24Bit data acquisition system, with high resolution, can be expanded to 8-channel AD acquisition.

6:USB1。 1. Communication, with the communication rate of 12Mb/s, adopts full speed mode and batch transmission mode.

7: The system board adopts the unique anti-interference wiring method of 4-layer PCB, with strong anti-interference ability.

8: Except for the power interface, all other interfaces adopt the standard USB interface. Plug and play interface This interface can realize hot plug, that is, it has the plug and play function. Interface characteristics can be set online by software. The layout of each interface is neat and reasonable, and it is convenient to plug and unplug.

9: The whole control system has high cost performance and high reliability.

10: The whole test process is controlled by microcomputer, and the load value, displacement value, deformation value, test speed and test curve are displayed dynamically in real time.

11: The microcomputer is used for data processing and analysis, and the test results can be saved automatically. After the test, the test curve can be recalled, and the test process can be reproduced through curve traversal, or curve comparison and curve amplification can be performed.

12: The test software under Windows platform in full Chinese has strong data and graphics processing functions, and can print complete test reports and test curves in real time.

13: It has perfect safety protection functions such as limit protection, overload protection and emergency stop.

Standards met:

GB/T16491-1996 Electronic Universal Testing Machine

Application industry:

Metrological quality inspection; Rubber and plastic; Metallurgical steel; Machinery manufacturing; Electronic appliances; Automobile production; Textile chemical fiber; Wire and cable; Packaging materials and food; Instruments and Apparatuses; medical apparatus and instruments; Civil nuclear energy; Civil aviation; Colleges and universities; Scientific research laboratory; The commodity inspection arbitration and technical supervision departments; Building materials ceramics; Petrochemical industry; Other industries.

Standard configuration:

1 set of stretching clamp; 1 set of bending fixture; Compression clamp 1 set

Expandable configuration:

Electronic extensometer; Large deformation (rotary or fixed); High and low temperature box, fixture or specially designed fixture and accessories can be selected according to the test standard or test sample provided by the customer, and the cost is calculated separately.

Technical parameters:

Model DR-6001

Maximum test force of measured parameters 1kN, 2kN, 5kN

10kN、20kN、30kN、50kN

Testing machine level 0. Level 5/Level 1

Test force measurement range 0. 4%~100%FS/0。 2%~100%FS

The relative error of test force indication is ± 0. 5%/±1。 Within 0%

Test force resolution 1/350000FS

Deformation measurement range 0. 2~100%FS

The relative error of deformation indication is ± 0. Within 50%

Deformation resolution 1/350000FS

Large deformation measurement range 10~800mm

The relative error of large deformation indication is ± 0. Within 50%

Large deformation resolution is 0. 008mm

The relative error of beam displacement indication is ± 0. Within 50%

Displacement resolution is 0. 06 μ m

Control parameter force control rate adjustment range 0. 005~5%FS/S

Relative error of force control rate is within ± 1% of the set value

The deformation rate adjustment range is 0. 02~5%FS/S

The relative error rate of deformation control rate is<0. 0.5% FS, within ± 2% of the set value; Rate ≥ 0. At 05% FS, it is ± 0 of the set value. Within 5%

The adjustment range of beam speed is 0. 001~500mm/min

± 0 of the set value of the relative error of beam speed. 5/±1。 Within 0%

The control range of constant force, constant deformation and constant displacement is 0. 5%~100%FS

When the set value of control accuracy of constant force, constant deformation and constant displacement is ≥ 10% FS, ± 0 of the set value. Within 1%;

When the set value is less than 10% FS, within ± 1% of the set value;

Other effective test width 420mm

Maximum stroke of beam (without clamp) 1150mm

Maximum travel of cross beam (with clamp) 850 (with XSD204B)

Mainframe size 775mm × 660mm × 1735mm

Power supply 220 ± 10%; 400/1kW

Main engine weight 400kg

-

CS tester FSM-6000LE glass surface stress meter

Learn more>>

CS tester FSM-6000LE glass surface stress meter

CS tester FSM-6000LE glass surface stress meter, with small automatic measurement error, is widely used in chemical flat glass manufacturers such as LCD and touch panel manufacturers. Tempered glass stress meter, FSM-6000LE glass surface stress meter is used to measure chemically strengthened and physically strengthened glass

Learn more>>

-

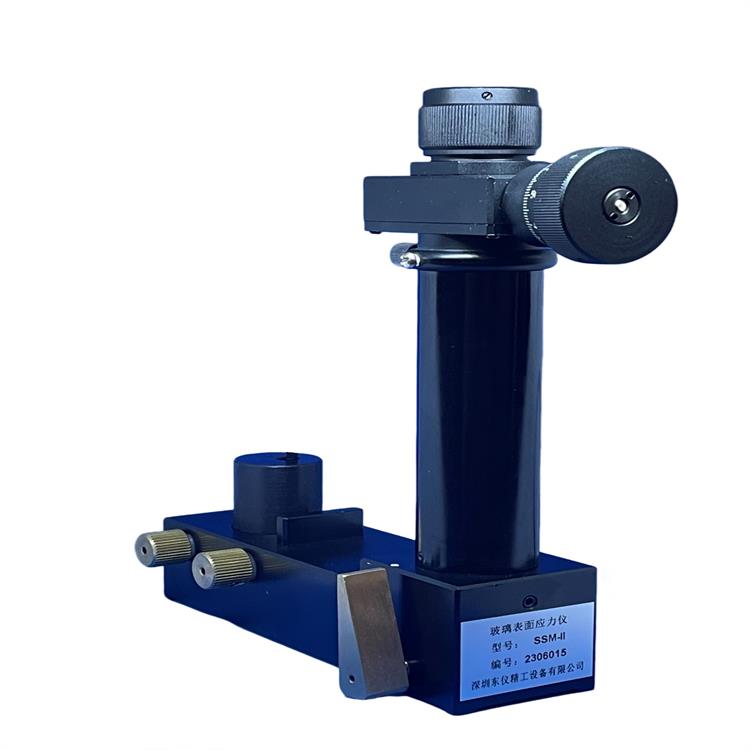

SSM-II glass surface stress meter

Learn more>>

SSM-II glass surface stress meter

SSM-II glass surface stress meter uses the optical waveguide effect caused by the tin diffusion layer on the surface of float glass to measure the surface stress quantitatively.

Learn more>>

-

Surface stress tester FSM-6000LE

Learn more>>

Surface stress tester FSM-6000LE

It is mainly used to measure the surface stress of chemically strengthened and physically strengthened glass

Learn more>>

-

Polarization stress meter LSM-4403

Learn more>>

Polarization stress meter LSM-4403

The automatic measurement error of the tempered glass stress meter FSM-6000LE is small. It is widely used in chemical flat glass manufacturers and touch panel manufacturers, such as LCD screen manufacturers. Tempered glass stress meter, FSM-6000LE glass surface stress meter is used to measure the surface stress of chemically strengthened and physically strengthened glass.

Learn more>>

Professional agent of well-known instruments and equipment at home and abroad

Provide professional laboratory solutions and equipment support

- Strong technical R&D team

- Experienced and excellent technology and innovative ideas

- High quality product supporting star service

Leave us a message , please fill in the correct information so that we can contact you at the first time!